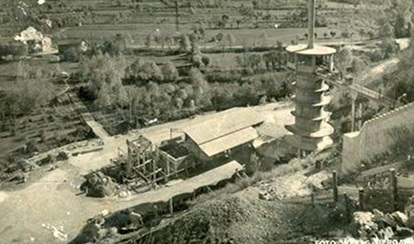

The first activity report of the Martina di Casazza quarry dates back to 1900, for the vein located on the right side of the Cherio river, 360-600 meters above sea level, in which, since 1971, Nicem Srl, a company owned by the Birolini family, has been doing business, the first Italian company to produce calcium carbonate.

Over 100 years working for men and for the environment

The high purity of the limestone from the Casazza vein (with a calcium carbonate ratio greater than 99.7%), along with Nicem’s constant investments in quality and technology, make it suitable for use in the most diverse sectors. In agriculture, ground and made into a very fine powder, it is spread over the soil as an acidity corrector, making it fertile and arable. In livestock management it is used as a feed supplement. Widely used also in the environmental industry: added to the coal burning process to produce electricity, calcium carbonate neutralizes sulfur pollution and purifies the fumes, and even produces an inert material (plasterboard), which can be used in construction. Calcium carbonate is used for remediation of reservoirs, to restore the ecosystem if polluted. Lastly, calcium carbonate is used in the cosmetic industry, as a natural inorganic pigment, as a detergent and thickening additive for toothpaste. At the Casazza the production process in the quarry is carried out in the name of quality, UNI EN ISO 9000 certified, and of the automated control of the entire cycle. The material, mined with explosives triggered by electric detonators, is brought to the production facilities that crush it in the following stages. The first phase uses jaw crushers, sieves, conveyor belts and magnetic iron removers to remove ferrous residues. The second phase is the grinding stage, first with hammer mills, then with ball mills to micronize the material. In some cases the most modern wind separators are even used get differently colored particles between 10 and 90 microns. The material is stored in silos and then marketed in bulk, in packages or in big-bags. The environmental awareness is evidenced not only by the environmental restoration of the quarry, started in 1993, with bioengineering and biotechnology solutions to grow complete and stable vegetation cover over the face of the quarry, but also thanks to the new project which will soon lead Nicem to work only underground. The project, drawn up in cooperation with the University of Mining Engineering of Turin and currently under construction, by excavating the preparatory tunnels, will create an innovative system of large chambers with sublevels: every chamber will be 70 meters high, 30 meters wide and 80-120 meters deep. The crushing plant will also be installed inside the rock, so as to totally avoid any environmental impact and the dispersion of dust, noise and vibrations.