NCT, founded in 1999, is a full-production-cycle company, which, starting from the mining of the raw material, offers a wide range of washed, selected and CE-marked aggregates. Inspired by its great tradition, experience and professionalism in the industry, and supported by highly qualified staff and a vein that, for the quality of its material, is technically classified as one of the best in the province of Bergamo, NCT focused its efforts on offering its customers the best possible product quality.

Its continuous quest for new types of production, high-tech equipment and materials with higher yields, supports its effort. The reduction of downtime due to failures, and careful preventive and scheduled maintenance, allow a long-term production continuity, make it possible to lower operating costs and makes sure there are no accidents on the job. The management and the employees share a strong concern for the company’s safety factor and the tranquility of the work cycle. Last but not least are the social and environmental factors, for which the company is working on redevelopment projects in the area.

The company, though founded recently, has distinct strengths:

• highly qualified personnel, given the number of years of experience in the industry – to ensure reliability ;

• a vein that, as to the quality of its material, it is technically classified as one of the best in the province of Bergamo – to ensure quality;

• a strong determination to succeed in offering an increasingly broad range of selected aggregates and to obtain the UNI EN ISO 9001 quality system – to ensure safety.

After its initial first years of business, starting from 2005, NCT set up technically advanced stationary plants, totally automated and remotely managed via computer control for every single step of the entire production process.

Thanks to its collaboration with the Milan Polytechnic, there is an active project to monitor production costs.

A program, recently installed in the plants, supervises the automatic operation of the quarrying operations.

Using sensors, energy consumption measurement instruments (a project implemented by Servitec of Dalmine) and no less than 9 weighing systems installed on separate conveyors, all the relevant data are sent to the central computer for the technical and economic analysis of production management.

Thus, NCT is a full-production-cycle company, which, starting from the mining of the raw material, offers a broad range of washed, selected and CE 2+ marked aggregates. The quality of the products offered is matched by the quality of the process, currently close to achieving certification, and the attention to safety, made possible not only by the automation of the production cycle, but also by regular meetings with the staff. Great attention is paid to the environmental aspects, shaping the business to comply with atmospheric emission requirements and the reuse of the resources used in the production process.

Since 2013, the company also produces prepackaged concretes marketed through Calberg Srl, which has been providing controlled and guaranteed quality prepackaged concretes for over 25 years, to the whole the area of the province of Bergamo and the surrounding areas.

Thanks to the close cooperation with the other members of the group, the customer can count on several concrete plants located throughout the territory and more than 100 vehicles, and a concrete production which places Calberg S.r.l. as an industry leader.

Certifications, awards CE-marked aggregates

Introduction Products and Services (max. 1000 characters)

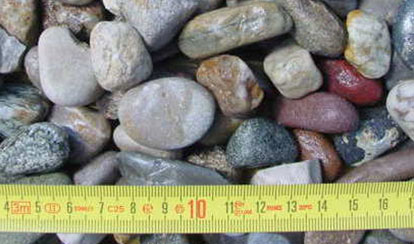

Natural aggregates:

Sieved sand 0/4 (fine aggreg. 0/2 round natur.)

Sand 0/10 (mixed aggreg. 0/8 round natur.)

Mix 0/20

Mix 0/30

Gravel 10/20

Gravel 20/30

Crs. Gravel 30/150

Pebbles 150/250

Natur. quarry mix

0/2 “Ticino” sand

Soil

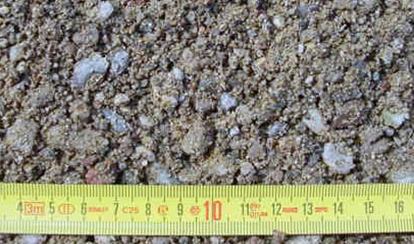

Crushed aggregates:

Washed crushed sand washed 0/3 (fine aggreg. 0/4 crush. Natur.)

Crushed stone 3/6 (rough aggreg. 2/5 crush. natur.)

Crushed stone 6/12 (rough aggreg. 4/11 crush. natur.)

Crushed mix 0/30 (mix. aggreg. 0/32 crush. natur.)

Guaranteed performance concrete UNI 11104:2004

Concrete whose properties and additional required features are specified to the manufacturer, who is responsible for providing a concrete that respects the applicable laws.

Concrete with requested composition

Concrete for which the composition is specified by the manufacturer, who is responsible for the compliance with such specification:

the dosage of cement (in Kg/m3)

the type and strength class of the concrete

the maximum diameter of aggregates

the granulometric composition of the mixture of aggregates

the type and dosage of additives or added material

the consistency class or water/cement ratio

The mixture of aggregates is optimized according to the cubic curve, unless a full prescription is provided by the client.